Grinding and Reconditioning

GESCO, Inc has provided precision tool engineering service to the industrial marketplace for 40 years. GESCO’s, Inc. services include grinding, reconditioning and remanufacture of industrial knives and precision tooling.

GESCO, Inc. provides complete reconditioning programs for:

- Slitter Knives

- Rubber Stripper Rings

- Shear Knives

- Hot Shear Knives

- Scrap Chopper Knives

- Bar Mill Shear Knives

- Roll Grinding

- Curve Crop Knives

- Side Trimmer Knives

- Forging Dies

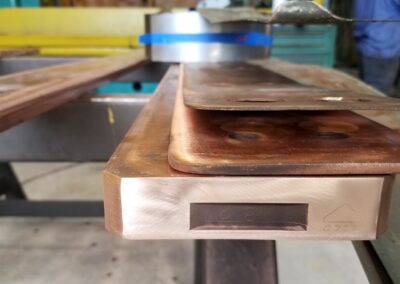

- Electrodes

- Wear Plates

- Slide Jaws

- Welder Dies (Reconditioned with new parts)

- Shear Blocks (Reconditioned with new parts)

Each product has a reconditioning plan with Work Instructions unique to the customer’s specifications. An inspection report is provided upon delivery of the reconditioned tooling. GESCO, Inc. maintains a history of all customers’ tooling and inspection reports.

Grinding Capabilities

- Surface (Vertical Spindle) 22″ wide x 169″ length

- Surface (Horizontal Spindle) 42″ wide x 200″ length

- Blanchard: 48″ swing x 30″ high

- Cylindrical: 42″ swing x 72″ length

- Roll grinding including crowing: 28″ swing x 168″ length

- Rotary Curve Crop up to 100″ length

- Surface (Horizontal Spindle) 42″ wide x 144″ length

- Surface (Horizontal Spindle) 30″ wide x 192″ length

- Blanchard 42’’ swing

- Cylindrical 26’’ swing x 168’’ length

- Steel and Rubber Roll grinding including crown 28’’ swing x 168’’ length

Reconditioning & Remanufacturing

- Complete Shear and Slitter Knife Sharpening Including Bar Mill and Curve Crop Knives

- Carbide Slitter Knives

- Welder Die Repair Including Manufacturing of Replacement Parts

- Liners and Wearing Plates

- Forging Dies

- Remanufacturing of slab knives by utilizing high nickel welding rod and precision finish grinding to achieve original dimensions.